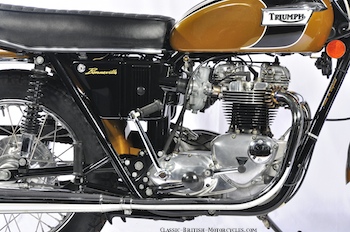

ABOVE: This 1971 Triumph Bonneville was restored to ‘better-than-new’ condition. It won “Best of Show” Award at the Clubman’s All-British Weekend 2011 motorcycle show.

TOTALLY NEW, BUT BETTER?

The 1971 Triumph Bonneville was a totally new bike. Only the engine carried over from 1970. Not since the 650 twin went unit construction in 1963 had so extensive a redesign taken place. 1971 model year started for the Triumph T120 Bonneville with Engine #NE01436. While the new frame & running gear were getting all the attention, the engine received some updates also.

LAST MINUTE ENGINE MODS

Most significant were the changes made to the cylinder head, head bolts & rocker boxes. These changes were engineered at the last minute by the Meriden factory when they found that the engine wouldn’t fit into the new oil-bearing frame. Their approach was brilliant & also yielded some added benefits. Gone were the tiny screw-in valve inspection caps. The headbolts were reworked so that they took the load off the already over-burdened rocker boxes & made the top end easier to torque down. Otherwise, there were minor changes to the pushrod tubes & their O-rings, a new crankshaft flywheel & bolts, and a new timing-side (right) main bearing. Changes were intentionally kept to a minimum because virtually every other part on the bike was new. Late in 1971, an optional 5-speed Quaife gearbox became available, originally an aftermarket item adopted by the factory race team. It would be next year before they would designate these 5-speed bikes differently, with a “V” suffix (ie: T120V). Gearing was lowered with a 47-tooth rear sprocket, in the interest of acceleration.

1971 TRIUMPH BONNEVILLE GETS NEW OIL BEARING FRAME

Of course, all the hub bub was over the new oil-bearing frame & all its accompanying new running gear. Very little was carried over from the pre-1971 650 Twin family. The old brazed & lugged frame, as good as it was (they handled great, tough & rigid) was replaced by a brand-new design, created in a brand new way aerospace engineers instead of motorcycle geeks, from BSA’s posh new ‘technology center’, a mansion nestled in the English countryside called Umberslade Hall. Big things were expected to come from this new brain trust, important new products, leading-edge technologies, that would save Triumph, BSA & Norton Motorcycles. This new frame was just the first of many great things to come…right?

1971 TRIUMPH BONNEVILLE NEW, BUT NOT SO IMPROVED

Unfortunately, for all the fuss, it really wasn’t a very good frame, it had been badly conceived, poorly designed, badly executed, and perhaps more telling, was completely unnecessary. The 1971 Triumph Bonneville needed many things, but a new frame carrying its own oil was not one of them. Vast resources were spent that could better have been invested in a good electric starter. But alas, we got the oil-bearing frame. Such was the wisdom of the leadership at BSA in those days.

1971 TRIUMPH BONNEVILLE SUFFERS AN OIL SHORTAGE

The new frame was all welded, no more brazed cast lugs. A enormous 3″ diameter round backbone extended from the steering head back under the tank, then straight down to a small sump at the bottom of the frame. The oil filler cap & dip stick were located just under the nose of the seat, where the backbone curved down. This meant that all the backbone’s interior volume from there to the steering head was not being used, which limited oil capacity in this lower section of the frame to just 4 pints. Triumph 650s generally have had 5- to 6-pint oil tanks. This again was due to bad planning on the part of the ‘brain trust’. There was a removable cast aluminum finned cover plate on the bottom of the frame sump with a filter screen inside of it. The gold “Made in England” transfer appeared for the first time, on the right front downtube, just south of the neck.

1971 TRIUMPH BONNEVILLE FRAME OFFERS SOME BENEFITS

Harking back to the pre-unit days, this new frame had twin front downtubes (just like the dreaded ‘duplex frame’, 1960-1962, but no such problems here) which cradled the engine, tied in with the swing arm pivot, then angled up to the top of the rear shocks, all in one unbroken piece of steel tubing. Plenty of crossmembers & bracing made the frame rigid & tough. There was a tendency of the left tube to bend at the kickstand. This was caused by the abrupt loads placed on it during kickstarting. It was therefore advisable to kickstart the bike on the centerstand. An aftermarket fix was retrofitted years later. Of course, a new frame meant that all the ancillaries had to be changed also. Engine plates, swing arm, shocks, battery box, rear fender, air filters, tank, seat, footpegs, chainguard, everything was new for 1971. As part of the ‘forward thinking’ of BSA’s plan, this new frame would be shared by the Triumph 650 twin & the BSA 650 twin. Of course, BSA production stopped barely one year later.

TOO TALL BONNIE

When introduced, the new frame pushed the seat height up to 32-1/2″, putting many riders up on their tippy-toes at traffic lights, another blunder on the part of the ‘Whiz Kids’ at Umberslade Hall. By 1972, the seat rails were relocated to bring the seat back down to a more normal 30″.

1971 TRIUMPH BONNEVILLE FRONT END

The new front forks were quite attractive, with sort of a “Ceriani”-look, very popular at the time. Now with internal springs, the chromed fork legs were exposed (no gators or sheetmetal covers), with alloy sliders with 4-bolt caps on the bottoms to secure the front axle. Early ’71s suffered premature fork seal failure, but improved seals in production solved this. The new black-enameled steel yokes turned on tapered roller bearings now, giving smooth, precise steering. Wheel & tire sizes were now 3.25 X 19″ front & 4.00 X 18″ rear with Dunlop K70 tires as standard equipment.

1971 TRIUMPH BONNEVILLE CONICAL HUBS

Another prominent feature of the new 1971 Triumph Bonneville and the Triumph TR6 also, were the conical front & rear brake hubs. They looked very cool, racer-inspired, but alas they didn’t work as well as the units they replaced. The front is a 8″ TLS (Twin Leading Shoe) set-up with an agressive-looking front air scoop. This is still one of the coolest looking front brakes you can find & today are favorites of builders & customizers for cafe racer, choppers, bobbers & street trackers. Part of the problem with the poor performance of the front unit was the odd way the cable actuated the cams. Intead of anchoring the outer cable to the backing plate, then attaching the inner cable to an actuator arm, which operated a linkage to a second arm (the way most TLS brakes are set up), the boys at Umberslade Hall thought it would be a better idea to throw out decades of brake development (much of it gleaned on the racetrack) & invent a whole new way to actuate the brakes cams. They attached the outer cable to one actuator arm & the inner cable to the other arm & had them both pull against one another when the brake lever was pulled. It had poor leverage & one cam always seemed to pull harder than the other. The rear is a 7″ SLS (Single Leading Shoe) set up & worked well enough.

BSA’s MASTER PLAN?

It boggles the mind to consider why BSA would have lavished it’s scant resources on the development of an exotic, risky new front drum brake when they knew that a disk brake was right around the corner. Perhaps the better question is, why wait? Why didn’t they just come out with the disk brake in 1971? Honda had been putting them on the front of their big bikes for a couple of years now & it was increasingly becoming the norm in the industry.

NEW LOOK FOR THE 1971 TRIUMP BONNEVILLE

Besides all the mechanical changes, the new 1971 Triumph T120 Bonneville 650 had a new look to it also, one that put off some people, who thought it wasn’t as handsome a machine as the 1970 Triumph Bonneville. But it was still a nice-looking bike & as such it soldiered on for another 13 years.

BODYWORK

The seat was new and all the bodywork were new. The massive 3″ backbone required a complete redesign of the fuel tank, now 3-1/2 US gal for all markets. Late in the year, a larger 4 Imp. gal tank was fitted to UK & Export models. The new tanks rested on foam rubber pads on the backbone & were secured with a single bolt that ran through the center of the top of the tank into a bracket on the top of the backbone, all rubber-mounted & concealed by a handsome pop-in cap with a Triumph logo on it.

COLORS & TRIM

Standard colors for the 1971 Triumph T120 Bonneville were Tiger Gold & Black separated by White pinstripe (although the ‘gold’ looks more like ‘root beer brown’ to me). The steel fenders were again painted gold with a black stripe & white pinstripes. The front fender was quite short compared to 1970, with spindly new fender braces.

1971 TRIUMPH BONNEVILLE MIXED BITS

The headlight was an odd pancake-shaped affair held in place by flimsy chromed wire loops that looked sort of interesting but didn’t hold up well to vibration. Since the frame held the oil, there was no need for a separate oil tank. In its place was a large black cover on both sides to house the air cleaners which were now plumbed to the carburetors with rubber hoses (gone were the classic pancake filters).

1971 Triumph Bonneville SPECIFICATIONS

|

T120R Bonneville Engine type Displacement Bore & Stroke Compression Carburetors Ignition Engine output Primary drive Primary sprockets Clutch Gearbox, standard Ratios, overall: 1st, bottom 2nd 3rd 4th, top Gearbox, optional Ratios, overall: 1st, bottom 2nd 3rd 4th 5th, top Final drive Final drive sprockets Frame type Suspension, front Suspension, rear Brake, front Brake, rear Tire, front Tire, rear Fuel capacity Wheelbase Seat height Ground clearance Weight |

Roadster Air-cooled OHV vertical twin 649cc / 40.0 ci 71mm X 82mm / 2.79″ X 3.23″ 9.0:1 2- Amal Concentrics R930/9, 30mm Battery & coil, Lucas 49 bhp @ 6200 rpm 3/8″ triplex X 84 links Engine 29T X Clutch 58T Multi-plate, wet 4-speed constant-mesh, right-foot shift —- 11.8:1 8.17:1 6.76:1 5.84:1 5-speed constant-mesh, right-foot shift —- 12.78:1 9.07:1 6.92:1 5.89:1 4.95:1 5/5″ X .400″ X 3/8″ chain X 106 links Gearbox 19T X Rear 47T All-welded, oil-bearing large-tube backbone Telescopic fork, hydraulic damping 2-way Swing arm, 2 Girling dampers 8″ TLS drum, conical hub 7″ SLS drum, conical hub 3.25″ X 19″ Dunlop, ribbed 4.00″ X 18″ Dunlop, universal 3 Imp gal (US) / 4 Imp gal (UK & export) 56″ / 142 cm 34″ / 87.5 cm 7″ / 18 cm 395 lbs/ 179 kg |